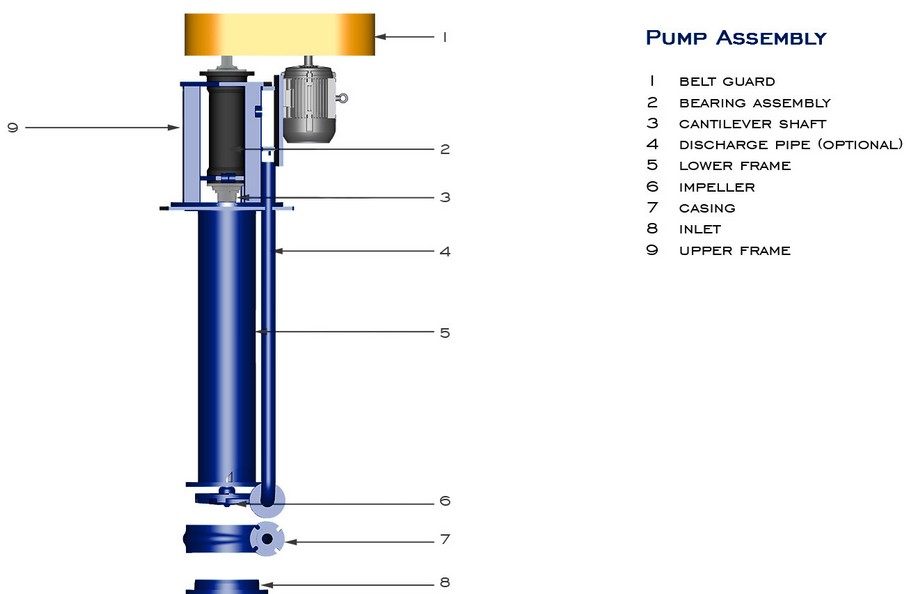

Heavy Duty Verticial Spindle Pumps

The Backbone of Vertical Pumping Solutions

Heavy-duty vertical spindle pumps are a critical component in industrial applications that require the transfer of large volumes of liquids, often against significant head pressures. These robust pumps are designed for durability, reliability, and efficiency, making them the go-to choice for a wide range of vertical pumping needs. In this write-up, we will delve into the key features, applications, and advantages of heavy-duty vertical spindle pumps.

Key Features of Heavy Duty Vertical Spindle Pumps:

Robust Construction

Heavy-duty vertical spindle pumps are engineered with sturdy materials such as cast iron, stainless steel, or high-performance alloys. This construction ensures their ability to withstand the rigors of demanding applications.

Vertical Design

The vertical orientation of these pumps allows them to efficiently handle liquids in situations where a horizontal pump may be impractical. They are commonly employed for applications like sump pumping, pit dewatering, and chemical tank transfers.

High Flow Rates

These pumps are known for their high flow capacity. Their design incorporates large impellers and powerful motors, enabling them to move substantial volumes of liquid, even against significant head pressure.

Reliability

Heavy-duty vertical spindle pumps are revered for their reliability. They are equipped with advanced sealing systems to prevent leaks and reduce maintenance requirements, making them essential for industries where downtime is costly.

Applications of Heavy Duty Vertical Spindle Pumps:

Mining and Mineral Processing

These pumps are used in mines to dewater pits and move slurries. Their ability to handle high flow rates and abrasive materials is essential for the mining industry.

Wastewater Treatment

Municipal and industrial wastewater treatment plants rely on these pumps to transfer sewage, sludge, and effluent, ensuring efficient water management.

Chemical Processing

In the chemical industry, heavy-duty vertical spindle pumps are employed to transfer aggressive chemicals, acids, and caustic substances. Their resistance to corrosion is vital in chemical processing.

Power Generation

Power plants use these pumps for the circulation of cooling water, the removal of ash slurry, and the transfer of various liquids essential for power generation.

Construction and Infrastructure

Heavy-duty vertical spindle pumps are integral for construction and infrastructure projects. They are used to handle dewatering in excavations and deep foundation projects.

Advantages of Heavy Duty Vertical Spindle Pumps:

Efficient Liquid Handling

These pumps are optimized for moving large volumes of liquids efficiently, making them ideal for applications where high flow rates are required.

Space Efficiency

The vertical design of these pumps saves valuable floor space, making them suitable for environments with spatial constraints.

Durability

Heavy-duty vertical spindle pumps are built to last, minimizing maintenance and replacement costs, even when dealing with challenging materials.

Reliability and Low Downtime

Their advanced sealing systems and robust construction contribute to their reliability, reducing downtime and ensuring continuous operation.

Conclusion

Heavy-duty vertical spindle pumps are indispensable for a variety of industries where efficient and reliable vertical fluid transfer is required. Their robust construction, high flow rates, and resistance to wear and corrosion make them a preferred choice in demanding applications. From mining and chemical processing to wastewater treatment and power generation, heavy-duty vertical spindle pumps play a crucial role in maintaining industrial processes while ensuring long-term cost-efficiency and reliability.

Heavy Duty Verticial Spindle Pumps

The Backbone of Vertical Pumping Solutions

Heavy-duty vertical spindle pumps are a critical component in industrial applications that require the transfer of large volumes of liquids, often against significant head pressures. These robust pumps are designed for durability, reliability, and efficiency, making them the go-to choice for a wide range of vertical pumping needs. In this write-up, we will delve into the key features, applications, and advantages of heavy-duty vertical spindle pumps.

Contact Us

SMI Products

HD Metal Pump

Click here to learn more

FP Pump Range

Click here to learn more

MD Pump Range

Click here to learn more

HD-SP Pump Range

Click here to learn more

MD-TV Vertical Pump Range

Click here to learn more

HD-VS Vertical Pumps

Click here to learn more

ST Vertical Pumps

Click here to learn more

MF Froth Pump Range

Click here to learn more